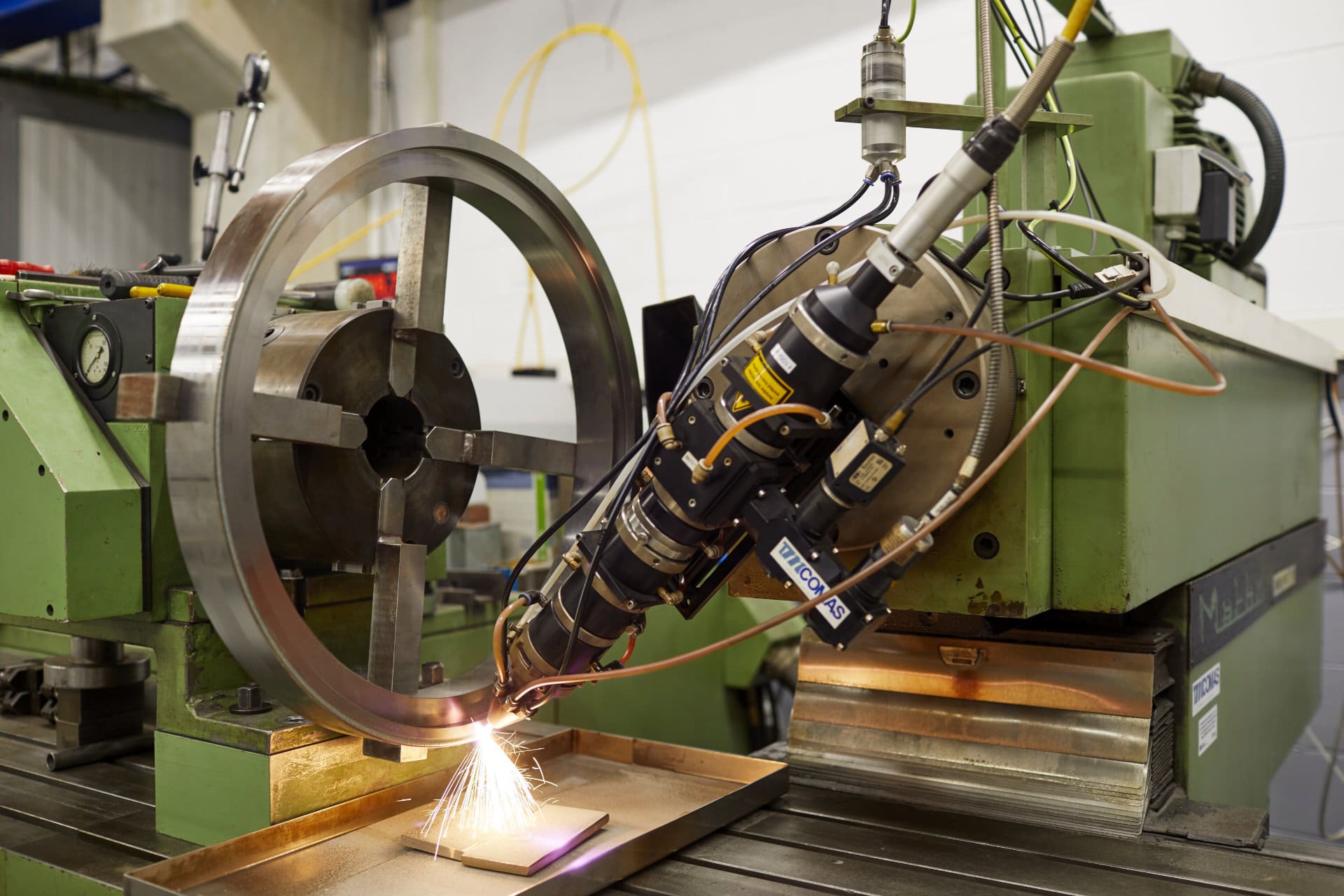

Laser Cladding

Life pieces improvement through the last generation technology.

At TMCOMAS we have almost 70 years of experience in mechanical and surface engineering and we are specialists in Laser Cladding.

Laser Cladding is the latest generation of coating technology that helps to improve the life of parts.

In TMCOMAS we are specialists in Laser Cladding, a last generation cladding technology that allows:

MATERIALS

- Co

- Ni

- Inox

- Cermets (WC)

- Last generation of cladding technology

- Wear and shock resistent hard facing coatings

- Corrosion resistant cladding

- Life pieces improvement

The main characteristics of Laser Cladding are:

- Lack of interconnected porosity.

- Very low dilution.

- Very low heat affected zone (zero thermal distortion).

- Strong adhesion (welding).

- Machinable and grindable.

- Refined metallographic structure, improved properties.

- High reproducibility (CNC).

- Laserline FDK VG4L 1000-4000 high power diode laser, 4000W peak power and wavelength from 900 to 1030 nm.

- Two-color optical pyrometer for process control.

- MacroCLAD 45V2 refill nozzle (1500 microns optical fiber).

- Positioning using 4-axis CNC-Cartesian machine.