Thermal Spray

High technology coatings for improving adhesion and mechanical properties.

At TMCOMAS we have almost 70 years of experience in mechanical and surface engineering and we are specialists in Thermal spray.

Since 1979, in TMCOMAS we are specialists in thermal spraying high-tech coatings by different methods:

Since 1979, in TMCOMAS we are specialists in thermal spraying high-tech coatings by different methods:

Procedures

Features

Benefits

PLASMA (APS)

- P: 0,5-3%

- T: 5.000-20.000ºC

- v: 200-500m/s

- Versatile

- Good Quality

- Ø interior ≥50mm

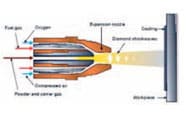

HVOF

- P: 0,5-2%

- T: 2.900ºC

- v: 425-1500m/s

- Better adhesion and mechanical properties

- Excellent carbide coatings on site

- On site

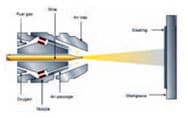

HVOF-W

- P: 0,5-2%

- T: 2.900ºC

- v: 425-1500m/s

- Better adhesion and mechanical properties

- On site

Arc Spray

- P: 3-6%

- T: 4.000ºC

- v: 150-170m/s

- Low cost, high efficiency

- Usability

- On site

Combustion

- P: 3-8%

- T: 3.100ºC

- v: 100-120m/s

- Low cost, high efficiency

- Ø interieur ≥50mm

- On site

| MATERIALS | APS | HVOF | FLAME SPRAY | ARC SPRAY |

|---|---|---|---|---|

| Metals | ✔ | ✔ | ✔ | ✔ |

| Alloys | ✔ | ✔ | ✔ | ✔ |

| Carbides | ✔ | ✔ | ||

| Oxides | ✔ |